Plyo boxes are a fantastic tool to improve your vertical jump by building explosive power and strength in your legs. If you workout at a CrossFit gym, the plyo boxes are typically narrower at the top and have a wider base, and this helps you to avoid scraping your shins along the top edge. This style of plyo box can be purchased online. But, if you are have a table saw, you can build them yourself using the DIY plyo box template below.

Note: This template was adapted from a well written plan published in the CrossFit Journal; however the layout they use requires two sheets of plywood.

However you can build two boxes with a SINGLE sheet of plywood using exactly the dimensions specified simply by laying out the pieces more intelligently. Here’s what I mean:

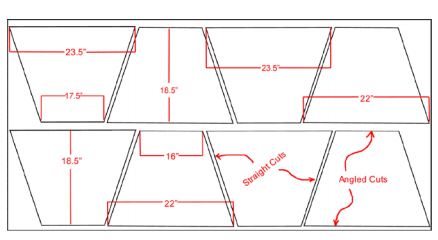

The picture below shows the 8 side pieces (for 2 plyometric boxes) laid out on a 4×8 foot piece of plywood. What you don’t see is the 10”x8’ section of the plywood that is wasted material. In the CF Journal DIY plyo box layout, you must cut a second piece of plywood for the 17.5”x 17.5” tops.

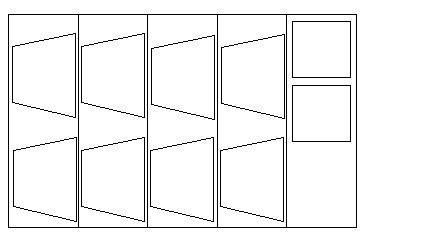

A better layout is shown below. This lets you build both plyometric boxes using a single sheet of hardwood plywood.

A few important points about materials:

- Use hardwood ¾ inch plywood – don’t buy the cheap stuff

- Pre-drill holes, use screws and not nails

- Use wood glue for greater strength

So for $40 and about an hour of work, I now have two solid plyometric boxes.

For additional reading, check out High-Powered Plyometrics 2nd Edition